Advances in technology have led to the manufacture of computer-controlled machines, better known as CNC machines. These devices, manipulated by professionally trained operators, are used in many industries such as metalworking, precision engineering, the consumer goods industry and more.

There are several types of CNC machines available on the market, each designed to perform specific operations on different materials and shapes. In this article, we will describe the most common types of CNC machines, what they are used for and their features.

CNC lathes and milling machines

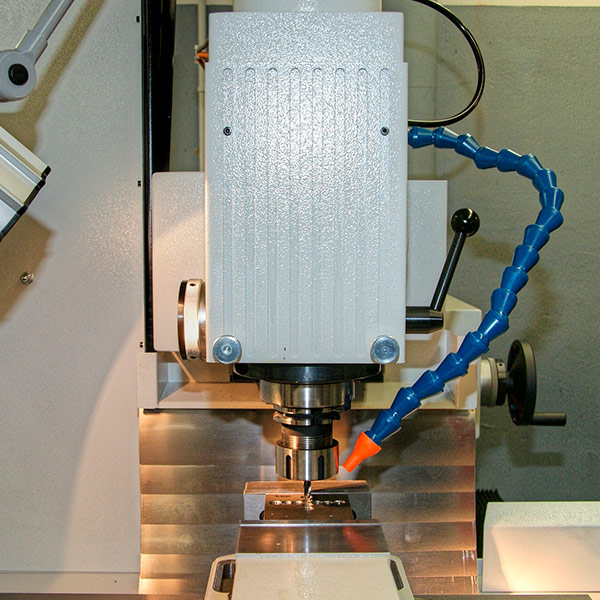

Both CNC milling machines and CNC lathes are manufacturing tools used to shape and cut materials into workpieces. However, there are some key differences between these two types of CNC machines.

The milling machine is primarily used to cut and shape solid materials by moving a cutting tool across the workpiece. CNC milling machines are capable of cutting materials in three dimensions along the X, Y and Z axes, and are often used for the production of highly precise and complex parts.

A CNC lathe, on the other hand, is essentially used to cut and shape cylindrical materials, such as tubes and rods. The cutting tool is clamped to the workpiece and rotates at high speed as it moves along the workpiece, cutting and shaping as it goes.

Plasma cutting machine

These CNC machines use an electric arc to cut electrically conductive materials such as steel, aluminum and copper.

The cutting process is accomplished by passing compressed gas through a nozzle, which generates an electric arc that ionizes the gas and converts it into plasma. The hot, concentrated plasma is able to melt and cut through the workpiece material.

Laser cutter

If you need to cut materials, such as metals, plastics and wood, into precise and complex shapes, a CNC laser cutting machine is ideal. The laser works by creating a high-intensity beam that melts and vaporizes the material.

Wire EDM machine

A CNC wire EDM machine is a tool that uses electricity to erode or cut electrically conductive materials, such as metals, to create complex and precise shapes.

The machine consists of a thin metal wire that moves through the material, removing small amounts of material with an electric spark controlled by CNC programming software.

Wire EDM machines are useful in the production of parts with complicated geometries and fine details, and are especially effective in the creation of molds.

Multifunctional CNC machines

These machines can be manipulated by a CNC operator to perform a variety of machining operations, such as turning, milling, drilling, laser cutting, plasma cutting, EDM, among others.

These are considered among the best CNC machines as they offer greater versatility and efficiency in manufacturing. They allow users to perform multiple operations without having to transfer the workpiece to another machine. In addition, these machines are capable of working with a wide variety of materials, including metals, plastics and composite materials.

However, it is important to note that multifunction CNC machines are typically more expensive than single CNC machines due to their greater complexity and capacity. In addition, they can be more complicated and costly to maintain and repair, as they involve multiple systems and components.

In general, multifunction CNC machines are ideal for those who need to perform multiple machining tasks and want greater efficiency and versatility in their manufacturing processes.