The world of CNC machining is vast and complex. At Solutions G00, we are proud of our expertise in this field and are here to share everything you need to know on the subject. Discover the details of the machining process, its importance in modern production, and how it can be optimized to maximize benefits.

Introduction to CNC Machining

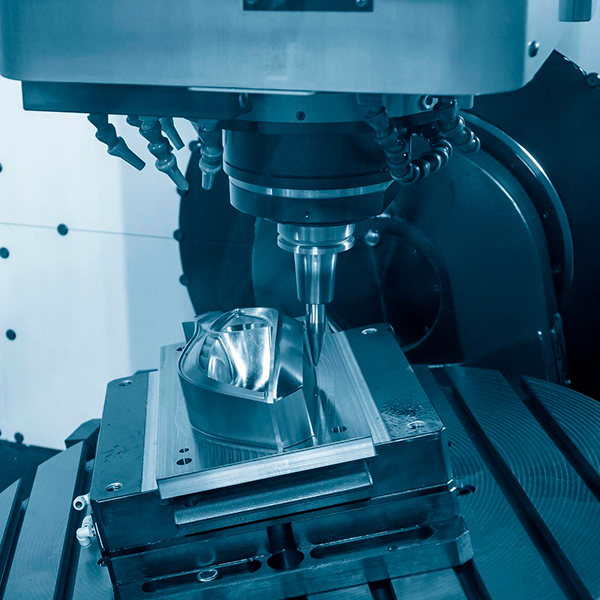

Computer Numerical Control machining, commonly known as CNC machining, is a manufacturing technique that uses computer-controlled machines to create precise and complex parts. Unlike manual machining where an operator directly controls the movements of the machine, CNC machining is fully automated, ensuring exceptional precision and reproducibility.

Benefits of CNC Machining

- Precision: One of the biggest advantages of CNC machining is its unparalleled precision. The machines are programmed to follow exact specifications, thus eliminating human errors.

- Speed: With CNC machining, production is accelerated. Machines can work 24/7 without requiring breaks, ensuring constant production.

- Flexibility: CNC machines can be quickly reprogrammed to produce different parts, offering unmatched flexibility in production.

The CNC Machining Process in Detail

The process of CNC machining begins with the design of a part on CAD (Computer-Aided Design) software. Once the design is finalized, the file is converted into instructions for the CNC machine. These instructions, called G-code, guide the machine throughout the manufacturing process.

The starting piece, often made of CNC aluminum, is mounted on the machine. The machine then follows the instructions from the G-code, meticulously removing excess material to produce the final part.

Specific Applications: Prototyping and CNC Aluminum

Prototyping is a major application of CNC machining. With its precision and speed, CNC is ideal for creating accurate prototypes in record time. Moreover, CNC aluminum machining is especially popular for its lightweight and durability, making aluminum one of the most popular materials in the CNC industry.

How Solutions G00 Can Help You

At Solutions G00, we understand the challenges associated with CNC machining. That’s why we offer a comprehensive range of services to assist companies in the machining field. Whether it’s CNC programming, technical advice, or strategic assistance, we are here to help.

Our mission is clear: to assist the manufacturing industry in filling the gaps in CNC programming and methodology. With our expertise and passion for machining, we are committed to making your company more competitive while reducing your operating costs.

Call on Solutions G00’s Programming Services

Our programming services offer multiple benefits in the short, medium, and long term, including:

- Urgent orders: We quickly respond to your most pressing needs.

- Complex projects: Our expertise allows us to handle the most technical and demanding projects.

- Lack of resources: We fill in resource gaps to ensure the continuity of your operations.

- Research and development: We support your innovation and development projects.

- Specific demand: We tailor our services to precisely meet your unique needs.

- Optimization: We provide solutions to improve and optimize your current processes.

If you need any of these CNC programming services in Quebec, contact us and one of our experts will provide you with all the necessary information about our remote and on-site services.

Conclusion

The world of CNC machining is constantly evolving. To stay competitive, it’s crucial to understand the nuances of the process and know how to optimize it. At Solutions G00, we have the knowledge and experience needed to guide you in this industry. Together, we can achieve wonders and propel your business to new heights.