Computer Numerical Control (CNC) programming is an essential part of modern manufacturing processes. It’s the brain behind the operation of machinery used in various industries, from automotive to aerospace. But what exactly is a CNC programming course and why is it so important?

Overview of CNC Programming

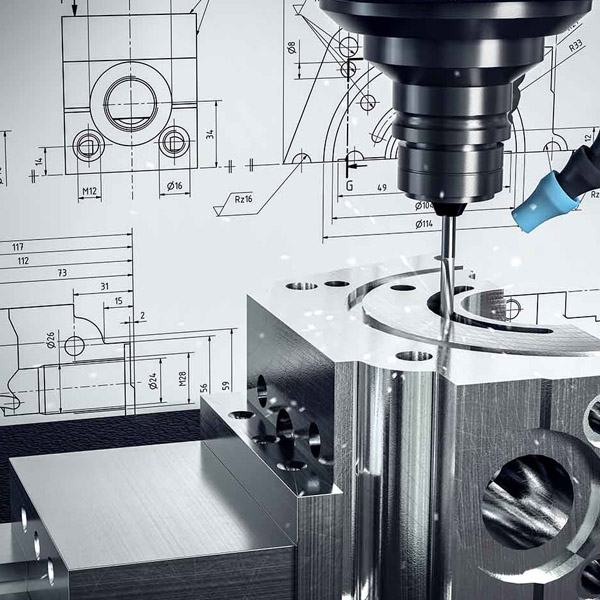

CNC programming refers to the process of designing instructions for CNC machines. These machines follow the programmed directives to produce parts with high precision and consistency. This revolutionary technology has transformed the manufacturing sector, making the manual operation almost obsolete.

The Need for CNC Programming

With the advent of Industry 4.0, the demand for skilled CNC programmers is on the rise. The ability to program CNC machines effectively and efficiently is a skill that’s now more valuable than ever. Isn’t it fascinating how this technology has taken over the manufacturing world?

Detailed Look at a CNC Programming Course

Now that we have understood the importance of CNC programming, let’s dive deeper into what a CNC programming course entails.

A typical CNC programming course covers various topics, including G-code programming, machine operations, CNC machining processes, and troubleshooting. These courses provide students with the necessary knowledge and skills to operate CNC machines and develop effective programs.

The learning modules of a CNC course consist of theoretical lessons, practical demonstrations, and hands-on practice. Most importantly, students learn to interpret technical drawings, write and modify CNC programs, and maintain CNC machines. It’s like learning a new language.

Significance of CNC Training

Let’s now turn our attention to the significance of CNC training. Practical CNC machinist training helps students apply their theoretical knowledge to real-world scenarios. It equips them with the skills to deal with machine malfunctions, programming errors, and production challenges. This practical exposure is crucial to prepare students for the manufacturing industry, don’t you think?

Real-world Applications of CNC Training

CNC training has wide-ranging applications in industries like automotive, aerospace, defense, and electronics. Skilled CNC machinists are responsible for producing high-precision parts and contributing to the advancement of these industries.

How Solutions-g00’s CNC Programming Course Stands Out

With numerous options available for CNC programming courses, why choose Solutions G00? Here’s why.

Solutions G00 offers a comprehensive CNC programming course that focuses on both theoretical knowledge and hands-on experience. We employ state-of-the-art equipment and software, ensuring students are well-prepared for the industry. Furthermore, we emphasize safety procedures and guidelines, giving students a holistic learning experience.

We offer a robust CNC programming course that comprises several comprehensive modules. Each of these modules is designed to equip students with the knowledge and skills necessary to excel in the CNC industry.

CNC Basics

This initial module introduces students to the fundamentals of CNC programming. It covers the principles of CNC machine operations, including the differences between various CNC machines, understanding of control functions, and the basic concepts of machine axes.

G-Code and M-Code Programming

The heart of CNC programming lies in mastering G-code and M-code, the languages used to control CNC machines. This module delves into the syntax and structure of these languages, teaching students how to write, read, and modify G-code and M-code instructions.

CNC Machining Processes

Here, students learn about different machining processes such as milling, turning, and drilling. This component enables them to understand the appropriate process to employ based on the design and material of the workpiece.

CAD/CAM Training

In this module, students gain hands-on experience with Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software. These tools are integral in modern CNC programming, as they facilitate the creation of complex designs and their conversion into executable CNC programs.

Safety Procedures and Guidelines

Safety is paramount in any industrial setting. This part of the course trains students on safety protocols, preventive maintenance, and troubleshooting of CNC machines, ensuring they can operate machinery safely and efficiently.

Practical CNC Machinist Training

The course culminates with practical training, where students apply their learned skills to real-world scenarios. They work on actual CNC machines, creating and executing their CNC programs, thereby getting a taste of the challenges and rewards of being a CNC machinist.

In a nutshell, Solutions-g00’s CNC programming course is a comprehensive package that promises a solid foundation in CNC programming, preparing students for a successful career in the industry. It’s an investment in your future.