In today’s highly competitive manufacturing landscape, staying ahead means embracing the most efficient and precise machining techniques. At Solutions G00, we specialize in leveraging cutting-edge machining operations to enhance productivity and reduce operational costs. This article delves into five essential machining techniques that are revolutionizing the industry.

1. High-Speed CNC Machining

Computer Numerical Control (CNC) Machining stands at the forefront of modern manufacturing. These machining techniques are crucial for industries requiring high-volume production with consistent quality. The acquisition of a new CNC milling machine in Spring 2021 (21″ x 18″ x 16″) at Solutions G00 exemplifies our commitment to top-tier manufacturing capabilities.

2. Precision Machining and Micromachining

As components become increasingly miniaturized, precision machining and micromachining have become indispensable. These machining techniques allow for the production of extremely small and intricate parts, essential in sectors like aerospace, medical, and electronics. The precision of these machining operations ensures high tolerance and exact specifications, vital for the functionality of small-scale components.

3. Multi-Axis Machining

Multi-axis machining offers unparalleled versatility in the manufacturing process. By operating on several axes simultaneously, complex parts can be machined in a single setup. This not only increases efficiency but also significantly enhances the precision of the final product. Multi-axis machines are a staple in advanced manufacturing environments, where complex geometries are common.

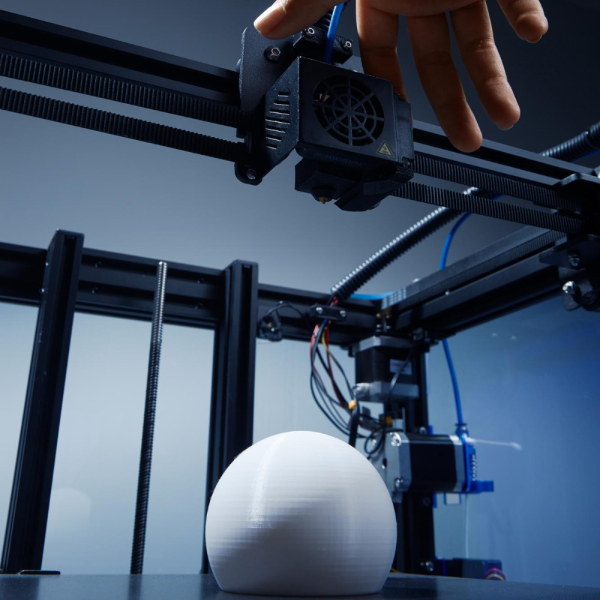

4. Additive Manufacturing and 3D Printing

While traditionally machining has been about subtracting material, additive manufacturing, including 3D printing, adds a new dimension. These machining techniques build objects layer by layer, offering unparalleled design freedom and material efficiency. Additive manufacturing is particularly beneficial for prototyping, custom parts, and complex geometries that would be challenging to machine otherwise.

5. Automated and Robotic Machining

Automation and robotics have transformed the machining process. Automated systems and robots can handle repetitive tasks with high precision and minimal downtime. This not only increases productivity but also reduces the likelihood of human error. Automation is key in achieving consistent quality, especially in high-volume production scenarios.

Technical Support and Consulting at Solutions G00

At Solutions G00, we often assist our clients in launching new projects. Our expertise in various machining techniques ensures that we provide the best strategic and technical advice to enhance your operations. With our own licenses for Mastercam and Fusion360, Solutions G00 offers comprehensive CNC programming services.

By offering training, you not only improve your workforce’s capabilities but also value and retain them. Solutions G00 offers training programs that can elevate your team’s skill set, keeping them at the forefront of modern machining techniques.

We can help you

In conclusion, embracing these five essential machining techniques can significantly boost your manufacturing capabilities. Solutions G00 is your partner in this journey, offering technical advice, CNC programming, and training services to help you stay competitive.

For comprehensive machining solutions and expert consultation, contact Solutions G00. Reach us at info@solutions-g00.com or call 514 632-0790. We are ready to elevate your manufacturing processes to the next level. Invite us to collaborate on your next project and witness the transformation in your manufacturing efficiency.