Manufacturing software is a specialized technological solution developed to automate and streamline the complex operations in a manufacturing company. It aims to boost efficiency, reduce errors, and promote decision-making based on data.

These multifaceted software applications are designed to consolidate various processes involved in manufacturing, from initial material procurement, scheduling, production tracking, to the final stages of delivery and shipment.

In essence, manufacturing software acts as the nervous system of a manufacturing setup, enabling smooth and optimized operations.

The Necessity of Manufacturing Software for a Manufacturing Company

One of the most significant advantages of manufacturing software is its potential to streamline the entire production process. The software provides real-time information about the different stages of production, enabling supervisors to make informed decisions quickly. This, in turn, minimizes downtime, reduces production delays, and ensures a smoother, more efficient workflow.

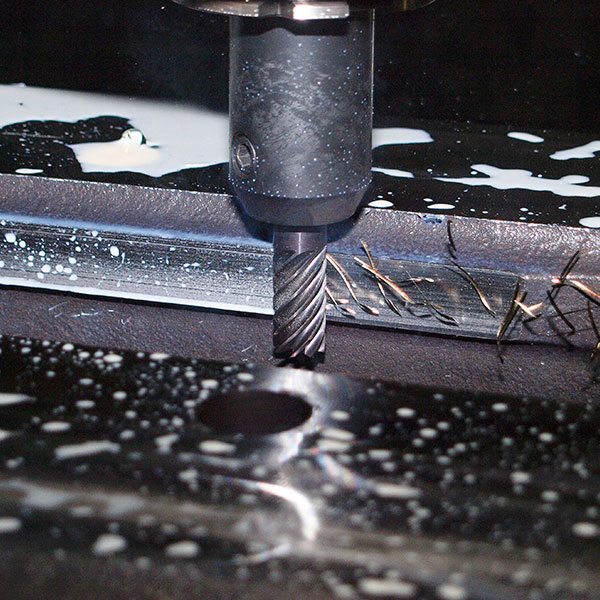

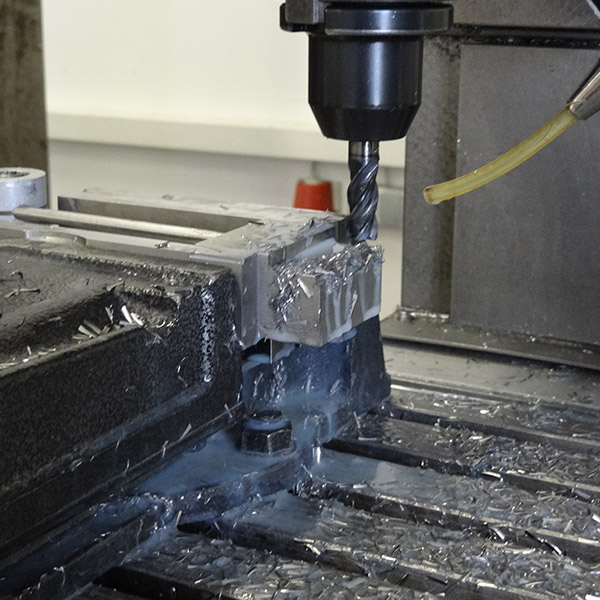

Computer Numerical Control (CNC) manufacturing software is an integral part of the modern manufacturing landscape. This sophisticated software provides a platform to design and implement the automated control of manufacturing processes, particularly those using CNC machines.

These high-tech machines, which can include milling machines, lathes, and plasma cutters, work by following programmed instructions without manual intervention, ensuring precise, accurate, and repeatable results.

Key Features of CNC Manufacturing Software

CNC manufacturing software comes equipped with a variety of features tailored for streamlined and efficient operations. These can include CAD/CAM integration, real-time monitoring, predictive analytics, and comprehensive reporting.

The CAD/CAM integration allows for direct translation of design data into manufacturing instructions for the CNC machines. Real-time monitoring helps in tracking the production progress and machine performance, while predictive analytics and reporting aid in decision-making and future planning.

One of the primary benefits of using CNC manufacturing software is the significant improvement in production efficiency. By automating the manufacturing process, businesses can produce high volumes of products with consistent quality, minimal errors, and reduced lead times. Furthermore, the software’s capacity for precision machining can lead to reduced waste material, translating into cost savings.

Flexibility and Adaptability with CNC Manufacturing Software

CNC manufacturing software is designed for flexibility and adaptability. Changes in the design or manufacturing process can be implemented by merely adjusting the software’s programming, avoiding the need for physical adjustments to the machinery. This feature is particularly beneficial in industries where customization and quick turnaround are critical.

The Role of CNC Machines in Manufacturing

CNC machines operate using pre-programmed sequences to control the movement of machining tools with utmost precision. CNC machines are popular in industries where exact repeatability and high accuracy are required, such as automotive, aerospace, and electronics.

CNC machines are designed to work in harmony with manufacturing software, forming a powerful combo that takes automation to a new level. The manufacturing software sends instructions directly to the CNC machines, detailing every aspect of the operation. This integration enhances precision, speeds up the production process, reduces manual errors, and increases overall productivity.

The Impact of Manufacturing System on the Industry

A well-integrated manufacturing system can significantly boost efficiency and productivity within a manufacturing setup. It enables real-time data collection and analytics, offering invaluable insights for performance optimization. With this data, manufacturers can identify areas that need improvement, plan resources more effectively, and make informed decisions that result in better productivity.

A manufacturing system’s benefits extend beyond improving operations, it also contributes to cost savings and sustainability. By minimizing waste, optimizing resources, and reducing production costs, manufacturers can achieve higher profitability.

As we look to the future, it’s clear that the future of manufacturing lies in harnessing such advanced systems. Those that adapt will not only survive but also thrive in this competitive industry.