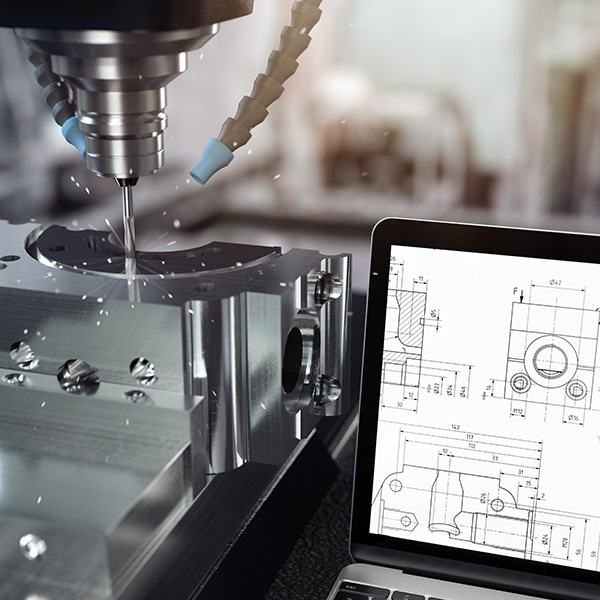

A CNC milling machine is an essential tool in today’s manufacturing world. The Computer Numerical Control (CNC) technology has transformed traditional processes into highly accurate, versatile, and efficient machines. This article will discuss what a CNC machine is, its uses, and the different types available.

The CNC Milling Machine Explained

A CNC milling machine is a computer-controlled machine that uses rotary cutters to remove material from a workpiece. The machine operates on three primary axes: X, Y, and Z, which represent the movement of the cutter in horizontal, vertical, and depth directions. The workpiece is fixed on a table, and the machine moves the cutter around the workpiece to shape it as desired.

The main advantage of a CNC machine over a conventional machine is its ability to follow computer-generated designs with high precision. This enables manufacturers to create complex parts and products with tight tolerances, reducing the need for manual intervention and improving overall efficiency.

Applications of a CNC Milling Machine

CNC milling is used in various industries, including aerospace, automotive, electronics, and medical. They are used to create a wide range of products and parts, such as engine components, circuit boards, and prosthetic limbs. Some of the primary applications of a CNC machine include:

- Prototyping: Engineers and designers often use them to create prototypes of new products. These prototypes help them identify potential design flaws and optimize the final product.

- Custom Parts: They allow manufacturers to create custom parts that would be difficult or impossible to produce using traditional manufacturing methods.

- High-Volume Production: Once a design has been finalized, CNC machines can produce large quantities of parts quickly and accurately, meeting the demands of high-volume production runs.

- Die and Mold Making: They are often used to create dies and molds used in injection molding and other manufacturing processes.

Types of CNC Milling Machines

There are various types of CNC milling machines available, each suited to specific applications and industries. Some common types include:

- Vertical Milling Machine: In these machines, the spindle is oriented vertically, allowing the machine to perform operations like drilling and plunge cutting. They are typically used for flat or slightly curved surfaces.

- Horizontal Milling Machine: These have a horizontally oriented spindle, making them better suited for machining grooves and slots on the sides of workpieces.

- Wood Milling Machine: Wood milling machines are designed specifically for woodworking applications. These machines can handle various types of wood and are often used in furniture making, cabinetry, and other wood-related industries.

- 5-Axis Milling Machine: These advanced CNC machines can move the cutter and workpiece in five different axes simultaneously, allowing for the creation of highly complex shapes and geometries. They are commonly used in aerospace and automotive industries.

Milling Machines in Canada

Canada has a robust manufacturing sector, with many companies utilizing CNC milling machines in their production processes. Several Canadian suppliers and manufacturers specialize in CNC milling machines, offering a wide range of options for businesses in various industries. For training and certification in CNC milling machine operation, the Canadian Manufacturers & Exporters (CME) and the Canadian Tooling & Machining Association (CTMA) offer valuable resources and support.

Our personal recommendation for your CNC milling machine needs in Canada, Solutions G00 is a highly recommended option. They have demonstrated their commitment to providing top-quality services by acquiring a state-of-the-art CNC milling machine (21″ x 18″ x 16″), equipped with a 4th axis. Solutions G00 offers a comprehensive range of services, including production, prototyping, turnkey projects, hands-on training, and specialized training in “probing” with the renowned Renishaw system. Their dedication to ensuring the highest quality results and client satisfaction makes Solutions G00 an excellent choice for businesses seeking expert CNC milling machine services in Canada.

Official Sources

To learn more about a milling machine and its applications, several official sources provide valuable information and insights. Some of these sources include:

- The International Journal of Machine Tools and Manufacture: This peer-reviewed journal publishes research articles on the latest developments and innovations in machine tool technology, including CNC machines.

- The National Institute for Metalworking Skills (NIMS): NIMS is a US-based organization that sets industry standards and certifications for various metalworking skills, including CNC milling machine operation.

- The European Association of Machine Tool Industries (CECIMO): CECIMO is a European trade association representing the interests of machine tool manufacturers, including those who produce CNC machines. Their website offers information on industry trends, statistics, and events.

- The Canadian Manufacturers & Exporters (CME): CME is Canada’s largest trade and industry association, representing the interests of Canadian manufacturers, including those who use CNC machines in their operations.

By consulting these official sources, businesses and individuals can stay up-to-date on the latest advances in this technology and ensure they are using the most efficient and effective methods in their manufacturing processes.

Conclusion

In summary, a CNC milling machine is a versatile and precise tool that has revolutionized the manufacturing industry. Its ability to create complex parts with high accuracy and speed makes it an indispensable asset for businesses across a wide range of sectors. With various types of machines available, such as wood milling machines, there is a machine suitable for every application. By staying informed through official sources and investing in the right equipment, manufacturers can continue to push the boundaries of innovation and efficiency in their operations.